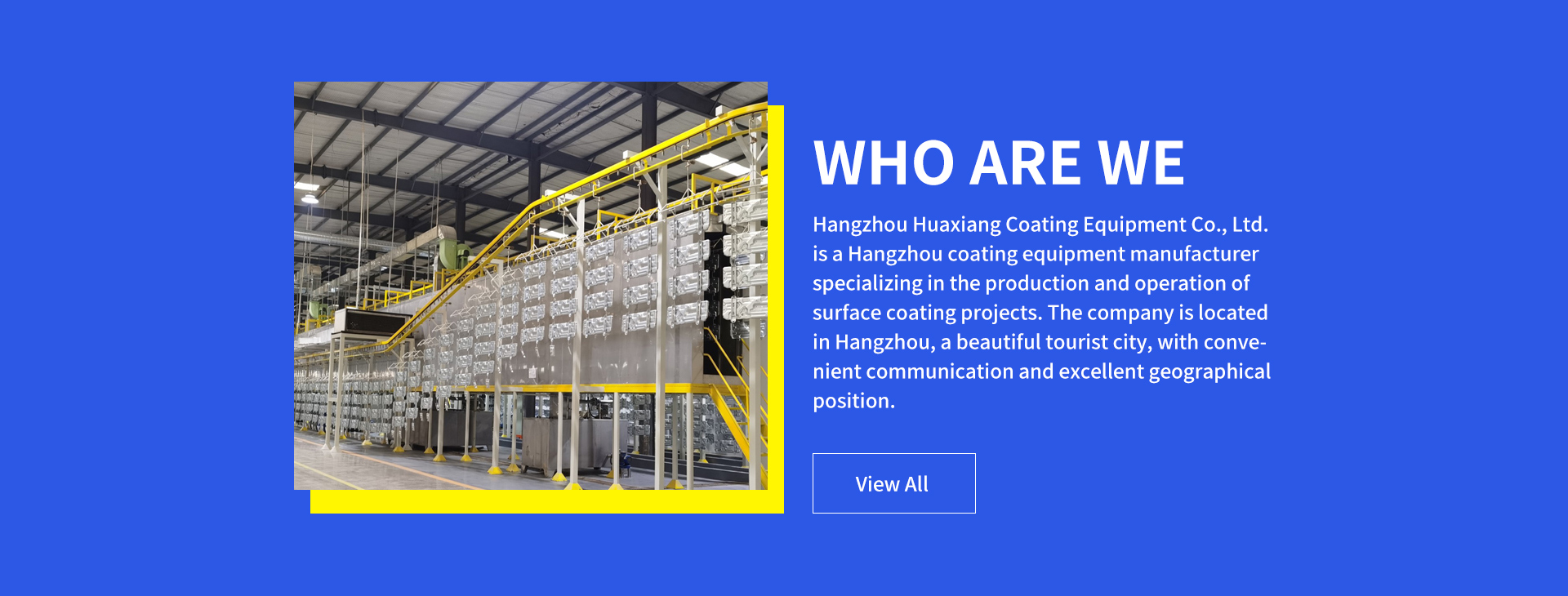

1. Aluminum Profile Powder Coating Line Supplier Equipment Overview

An Aluminum Profile Powder Coating Line Supplier provides specialized systems for coating aluminum profiles. Key components include pre-treatment stations (cleaning, chromating), electrostatic spray booths, conveyor systems, curing ovens, and powder recovery units. Leading suppliers like GEMA and Eisenmann offer advanced features such as robotic arms, PLC controls, and IoT-enabled diagnostics. Modular designs allow customization for high-volume or specialized production needs.

2. Applications of Aluminum Profile Powder Coating Lines

These systems are essential in architectural aluminum (window frames, façades), automotive (alloy wheels), and construction (structural beams). They coat profiles for solar panel frames, HVAC systems, and consumer electronics. The eco-friendly, zero-VOC process aligns with industries prioritizing sustainability and durability.

3. Aluminum Profile Powder Coating Line Price Ranges

Manual systems start at 50,000,semi−automatedunitsrangefrom150,000–500,000,andfullyautomatedlineswithroboticsexceed1 million. Costs depend on line length (20–100 meters), throughput (100–2,000 profiles/day), and features like energy recovery or AI-driven quality checks.

4. Best Practices for Operating Aluminum Profile Powder Coating Lines

Surface Prep: Degrease and apply chromate conversion coatings for adhesion.

Spray Settings: Adjust voltage (60–100 kV) and airflow (0.5–1.5 bar) for uniform coverage.

Curing: Bake at 180–220°C for 10–25 minutes; monitor with IR sensors.

Maintenance: Clean filters weekly and inspect conveyor belts monthly.

5. How to Choose an Aluminum Profile Powder Coating Line Supplier

Reputation: Prioritize suppliers with industry certifications (CE, ISO 9001) and positive client reviews.

Customization: Ensure suppliers offer modular designs for future scalability.

Technical Support: Opt for suppliers providing 24/7 customer service and spare parts.

Energy Efficiency: Choose systems with heat recovery and IoT diagnostics.

6. Safety Measures for Aluminum Profile Powder Coating Lines

Ventilation: Install explosion-proof exhaust systems to mitigate combustible dust risks.

Grounding: Maintain <1 ohm resistance across all conductive components.

PPE: Require NIOSH-approved respirators, anti-static suits, and safety goggles.

Fire Safety: Equip lines with thermal cutoff switches and Class D extinguishers.

7. Cost-Benefit of Supplier Systems

Modern systems reduce energy consumption by 25–40% through heat recovery and variable-speed drives. High transfer efficiency (70%+) minimizes material waste, while IoT integration slashes downtime via predictive maintenance. ROI is typically achieved within 12–24 months for high-volume producers.

8. FAQs on Aluminum Profile Powder Coating Line Suppliers

Q: How to verify the reliability of a powder coating line supplier?

A: Check certifications (CE, ISO), client reviews, and industry partnerships.

Q: Can suppliers customize lines for small workshops?

A: Yes, many offer compact, semi-automated systems tailored for SMEs.

Q: What maintenance ensures long-term performance?

A: Follow the supplier’s guidelines for filter replacement, nozzle cleaning, and sensor calibration.

Q: Are supplier warranties negotiable?

A: Some suppliers offer extended warranties for high-volume buyers.

Q: How do suppliers address environmental regulations?

A: Leading suppliers design systems with closed-loop recycling and zero-VOC emissions.

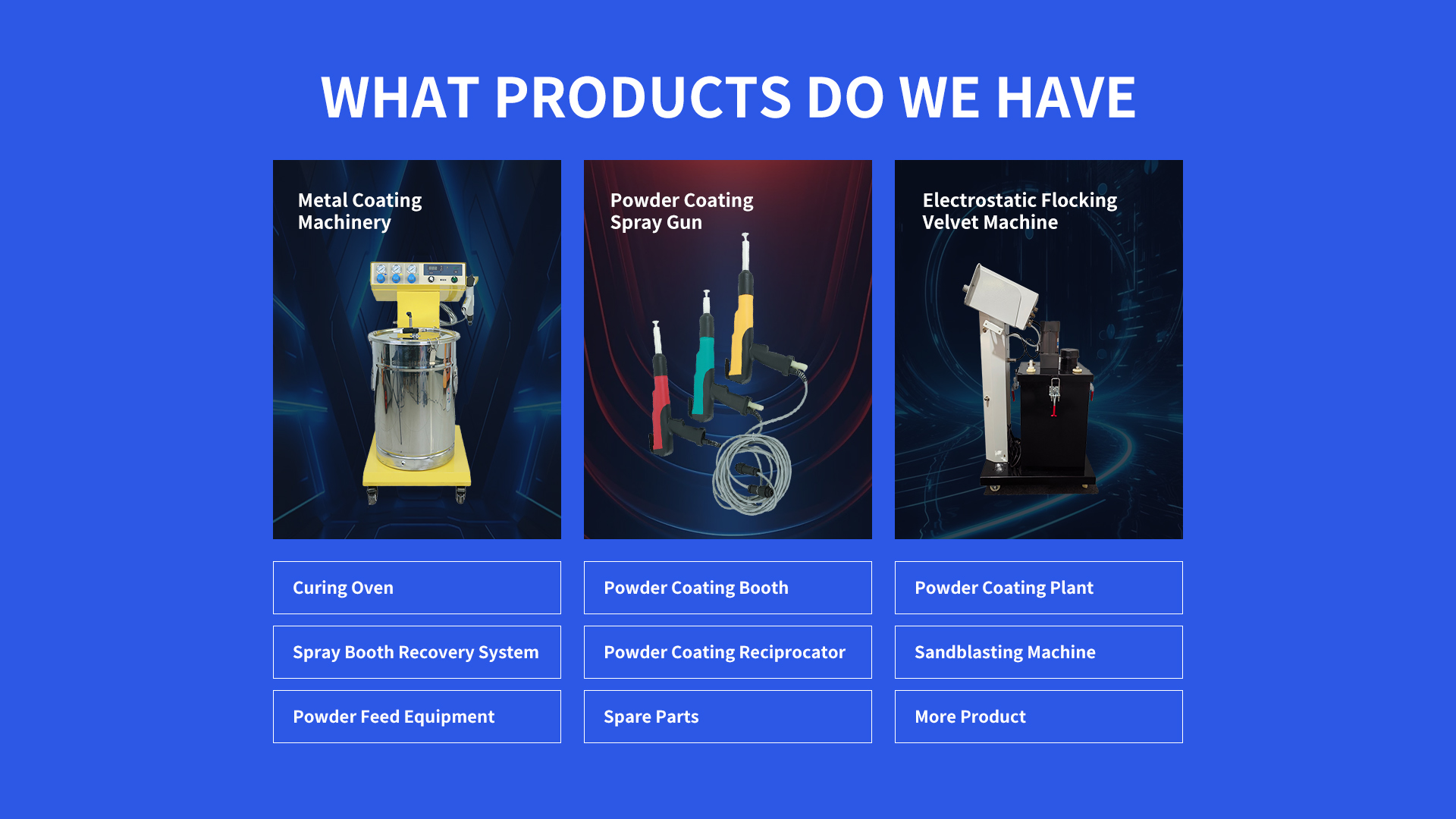

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com